Orbital Welding

Orbital welding a specialized area of welding that WS Associates’ partners are experts in.

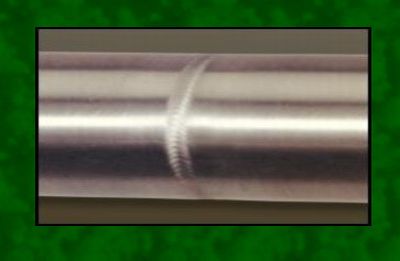

The welding arc is automatically rotated 360° around the workpiece – usually an object such as a tube – to create a high quality continuous weld.

Automated computer controlled orbital welding processes run completely independently without intervention from the operator. During welding, the weld parameters are continuously adjusted for each weld quadrant in order to have complete control over the weld pool, and therefore a perfect balance is maintained between gravitational force and surface tension at every position of the torch.

The main components of every orbital welding system are the power source and controller, the welding head and a wire feed mechanism. WS Associates manufacturers are able to control all important parameters such as arc length, magnitude and pulse frequency of the welding current, welding speed, inert shielding gas, parent material, filler material, weld preparation, and thermal conductivity. As a result a high quality weld is achieved throughout the entire workpiece.