Electropolishing

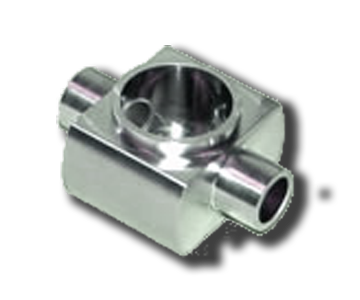

for Stainless Steel Gas Fittings and other High Purity Components

Electropolishing is a featured process at WS Associates’ manufacturing facilities. Electropolishing has many applications within the metals finishing industry; WS Associates is particularly skilled in high purity components, including stainless steel gas fittings and custom products and Assemblies for the Semiconductor, Biotech, Medical, Pharmaceutical, Industrial, and Aerospace Industries.

Electropolishing, also known as electrochemical polishing or electrolytic polishing, is an electrochemical process that removes material from a metallic workpiece. It is used to polish, passivate and deburr metal parts.

The parts immersed in a temperature controlled bath of concentrated acid or perchlorate electrolyte and connected to the positive terminal (anode) of a DC power supply, the negative terminal being attached to the cathode. A current passes from the anode, where metal on the surface is oxidized and dissolved in the electrolyte.

Electropolishing works by causing microscopic raised points of the component finish to be dissolved much more quickly than recessed areas, due to stronger electric fields and faster replenishment of the electrolytes at the peaks of the surface.