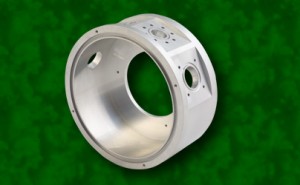

CNC Milling

CNC Horizontal and Vertical milling centers.

Milling machines are often classed as either horizontal and vertical, referring to the orientation of the main spindle.

Unlike a drill press, which holds the workpiece stationary as the drill moves axially to penetrate the material, milling machines also move the workpiece radially against the rotating milling cutter, which cuts on its sides as well as its tip. Workpiece and cutter movement are precisely controlled to less than 0.001 inch

Milling machines can perform a vast number of operations, from simple (e.g., slot and keyway cutting, planing, drilling) to complex (e.g., contouring).

The choice between vertical and horizontal spindle orientation in milling machine design usually hinges on the shape and size of a workpiece and the number of sides of the workpiece that require machining.

Work in which the spindle’s axial movement is normal to one plane, with an endmill as the cutter, lends itself to a vertical mill. Work needing machining on multiple sides lends itself to a horizontal machining center.